From garden shed to industrial building – ABUS single girder EOT crane in a woodworking factory in Switzerland

Timber is quite a versatile raw material as well as construction material: this is well demonstrated by the company Käser Holzbau (www.kaeser-holzbau.ch) in Weier, in the Emmental valley in west central Switzerland. Käser Holzbau has 20 personnel and is known in the region for their varied timber construction works, be it joinery work, building new wooden houses, carpentry works, wood construction systems, farm houses, or agricultural or industrial buildings. Timber is also the dominant material in the company’s own production and timber framing plant.

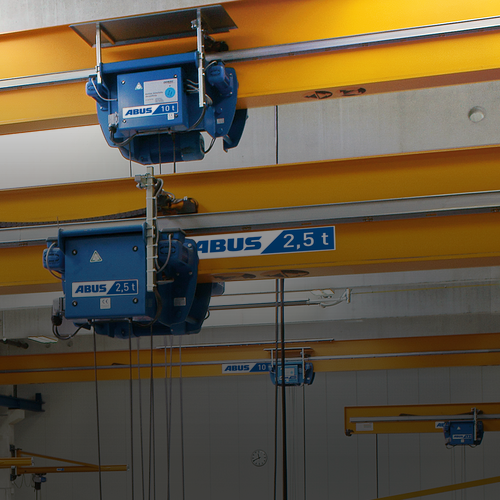

Timber is a very heavy material due to its characteristics and this is felt when transporting it inside the factory from one workstation to the next for example. Käser Holzbau has long been using an ABUS single girder EOT crane with a load capacity of 5 tonnes, however, this crane was predominantly used in the rear section of the hall. The company invested in a second single girder crane in order to have a crane available also in the front part of the building. This second crane is of the ELK type, the SWL is also 5 tonnes and the span is 20.9 metres. Every part of the plant can now be reached by one crane or the other. Both cranes feature monorail hoists type E, one of the most commonly used wire rope hoists for the lower load spectrum. This wire rope hoist is designed in a very compact way with favourable dimensions and features two direct drives for the trolley.

One of the cranes is mainly used to transport timber elements between workstations. The other crane will load finished elements onto lorries. Though both cranes travel on the same crane track they are separated by a wall that divides the hall into two working sections. Both EOT cranes are fitted with collision protections for long travelling. These collision protections at the end of the crane track consist of warning, braking and emergency stops. When the cranes travel over the first switching points they are slowed down and switched off when travelling over the second switching points. Travelling back is possible in fast crane travelling speed even when both points have been travelled over previously. Cross travelling also works according to the same principle of warning, braking and emergency stop. Thus impact on buffer at the crane track end stoppers and / or the hoist buffers is avoided as is the related load swing which means added safety for the crane user in particular when transporting long and heavy timber elements as are manufactured by Käser Holzbau.

The new crane is operated via an ABUS radio remote control, the ABURemote Button, which consists of a handheld transmitter with two-stage push buttons. The remote control enables the crane user to keep an eye on the load and to transport it safely from a safe place.

The complete project, from consultation right through to installation was handled by the company Brun Marti Dytan AG (www.brunmartidytan.ch), the Swiss agent of ABUS with headquarters in Nebikon in the canton of Lucerne in the centre of Switzerland. The first EOT crane, dating back to a project in 2008, had also been supplied and installed by Brun Marti Dytan AG.