ABUS cranes at RANDON Implementos in Brazil

It is not an easy task to optimise transport and logistics in a country of such continental proportions as Brazil. Already during the so-called Old Republic commencing in 1889 the government furthered road building. Even today roads are the most important transport arteries in the country amounting to about 1.8 millions of kilometres which makes them the fourth biggest road and motorway network worldwide. The most famous motorway in Brazil, called the Rio-São Paulo, was built in 1926 and remained Brazil’s only metalled road until 1940. The country-wide development of the road network attracted in its wake such major car manufacturers as Volkswagen, Ford, and General Motors building their production plants in different locations. The building of the road network and the subsequent establishment of the automobile industry are considered a symbol of the modernity of this era until this day. In this dynamic environment specialised companies emerged in the transport sector whose aim it was to optimise the transport of goods to different regions of the country on the one hand and on the other to increase safety on the roads. One of these companies is the company Randon S/A Implementos e Participações (www.randon.com.br), domiciled in Caxias do Sul in the southernmost state of Brazil, Rio Grande do Sul.

Randon is the largest manufacturer of trailers and semitrailers in all of South America with about 400,000 units sold. Randon have several production facilities and export their trailers to more than 70 countries. The product portfolio of Randon includes not only trailers and semitrailers of all kinds and sizes but also for different applications and for transport goods such as vehicles for bulk materials, tank and refrigerated trailers, and specialised vehicles for the transport of sugar cane.

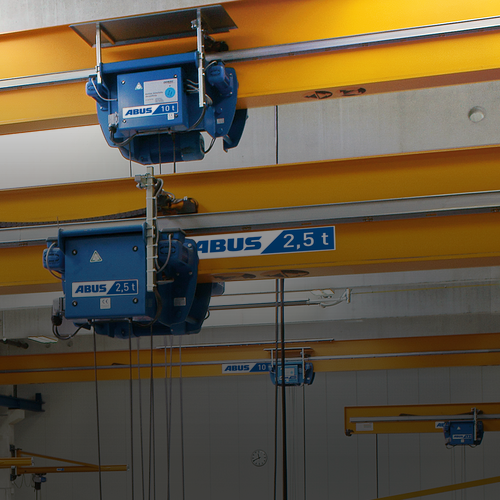

Logistics and material flow are also a key issue for Randon themselves. When Randon decided to optimise the material flow by altering the existing process sequence in their production they got in touch with the company Eidt-Ciriex (www.ciriexabus-cranes.com.br), the ABUS agent in Brazil with headquarters in Porto Alegre. Gustavo Trentin who is responsible for the analysis of engineering processes at Randon Implementos described the intended essential alterations of the production sequences thus: “In the past complete units, i.e. chassis and bodywork, were painted which required extensive covering and insulating work to be carried out. We introduced a new working area where chassis and bodywork are painted separately and built into a complete vehicle afterwards. This procedure was to increase substantially not only productivity but also the quality of the final product.” The modified production lines required also new cranes to be installed in the production areas. For over 16 years Randon had already been using ABUS crane systems with different designs and load capacities and this project too saw ABUS cranes being installed following the analysis of the transport task and consultation by Eidt-Ciriex.

The central units of the new crane systems are two single girder cranes with load capacities of 12.5 tonnes each. Both EOT cranes feature two electric wire rope hoists with SWL of 6.3 tonnes each. It is possible to operate both wire rope hoists on each crane in tandem operation or even to use both cranes in tandem depending on the shapes and sizes of the loads to be transported. The identically designed cranes move with the same speeds parallel in the targeted direction during tandem operation, i.e. long and cross travelling as well as lifting and lowering of the load are executed in duo. If both wire rope hoists of each crane and the cranes themselves are operated in tandem simultaneously then the loads can be attached in four different places during transport which leads to increased safety and ease of operation in particular when positioning the painted bodywork onto the chassis. It goes without saying that both cranes may operate independently in individual operation as soon as the function “tandem operation” has been cancelled. The cranes feature comprehensive safety functions given their complex operating situation, e.g. if one hoist suffers from overload both hoists will be stopped.

Randon have in their various production and installation plants a total of 62 electric wire rope hoists, 113 electric chain hoists, 19 EOT cranes, and 12 HB systems (modular light weight crane system for loads of up to 2 tonnes) in use.