FUTURE FIBRES - ABUS electric chain hoists to handle high-tech masts for sailing ships in Spanish company

Nearly everybody in the world has seen a regatta, either directly from the shore or on television. And everybody would agree that a regatta is an amazing spectacle attracting large numbers of onlookers. Regattas are really testing the skills of the participants as well as their endurance and that of their boats.

A great number of nautical events and competitions take place on the Mediterranean coast and in the town of Valencia in particular during the year. One of Valencia’s major events is the Trophy of Her Majesty the Queen which sees the best watercrafts participating. Given these high levels of competition, it is absolutely essential that the vessels involved can rely on the best designs and materials, in particular when it comes to such key parts as the masts and the whole array of fixtures (anchors, ropes, etc.), in short, the entire rigging.

The company FUTURE FIBRES (www.futurefibres.com) with headquarters in Valencia is the world leader in the design and the production of masts and rigging for all types of vessels for any use they might be put to: for competing, for recreation purposes, or for super yachts. One of the reasons for the great success of FUTURE FIBRES is “the right fibre for the right application” abbreviated to RFRA. This principle is grounded in the use of a mixture of distinct fibres such as PBO, carbon, Dyneema, and Kevlar in order to match the resulting products with the needs of each individual customer.

The material handling process is part of the production process which sometimes requires special treatment. Given the dimensions of the parts being produced, the company FUTURE FIBRES decided to introduce a better quality in their internal material handling process. Very large masts used to be handled by manual chain hoists which needed to be operated separately which in turn made the process of moving the masts extremely slow.

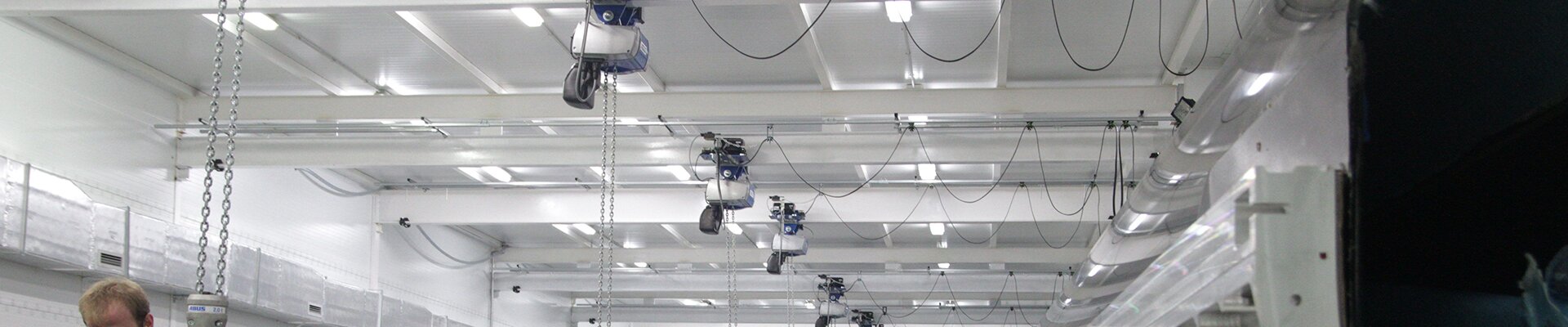

In order to improve this process of material handling the company FUTURE FIBRES trusted in ABUS. ABUS Grúas (www.abusgruas.es), the Spanish daughter company of the multinational company ABUS Kransysteme GmbH, worked hand in hand with FUTURE FIBRES in order to find the best solution for their requirements. The workflow was studied in detail and the installation of ten identical ABUS electric chain hoists was recommended. These chain hoists were of the GM6 type with a safe working load of 2000 kg each, with electric hoist travelling and a hook path of 4 metres. The two different speeds for each movement (which is a standard for all ABUS hoists) allow working in precision speed when starting to lift the load (or when setting it down in the new location) but also allow for swifter movement of the load when it is possible to take advantage of it. The investment in these ten chain hoists can be directly translated into considerable time savings. Comparing the synchronised ABUS electric chain hoists with the previously used manual hoists, the time savings achieved amount to 60% and as to staff needed the economisation is an even more impressive 90%: this particular work used to require the labour of ten persons and can now be accomplished by one person on their own.

The key factor in this improvement of the material handling process is found in the control of these chain hoists. The chain hoists are remote controlled with control units designed specifically for this project. The special design of the remote control and the ten receivers installed on the hoists allow the operator to operate all hoists with the same remote control. The operator can select the hoists he needs to operate simultaneously and the versatility of this solution really boggles the mind.

So from now on when we watch a regatta and we see the winning team then we will know that most likely FUTURE FIBRES have a share in the victory because they have known how to combine the materials thanks to their highly qualified professional staff and also because of the improvement of the production process thanks to the ABUS chain hoists.