Huge ABUS EOT crane at electric power supply company in Norway

Hydropower in Norway

Norway has a long tradition of making use of hydropower: It was in 1895 that the State of Norway acquired the first waterfall to generate power for a railway line thus setting a milestone for generating energy from hydropower. By now Norway generates 99% of its energy in either hydropower plants or in storage power plants. Hydropower and companies employed in this sector gain in importance in this era of renewable energies. Statkraft (www.statkraft.no), a State owned company with headquarters in Oslo, is the market leader in this business sector. Statkraft has historical links with hydropower even if it has been in existence in its current legal form only since 1992. Today Statkraft is looking after 234 hydropower plants, 141 of which are located in Norway and 59 in Sweden. A total of 3,400 staff work in more than 20 countries in order to satisfy the ever increasing demand for energy through innovation by researching and developing new sources of energy. In 2009 the first prototype worldwide of osmotic power was inaugurated near Oslo. Statkraft is also relying on the expansion of wind power plants in addition to hydropower.

New power plants at Eiriksdal and at Makkoren

The area around Høyanger on the wild cliffs of Norway’s west coast is rough but beautiful. Imposing mountains and rivers dominate the landscape. In 2010 Statkraft started to build two new power plants here. This project included not only building two new power plants but also comprehensive environment protection measures. In order to happily marry the harvesting of energy with protecting the environment Statkraft had to examine several options to realise this project. They finally decided on a model that saw three old power plants demolished and numerous renaturation measures carried out. Overhead power cables were to be replaced by cable routes and large parts of the river Dale were to be relocated to its old riverbed. Statkraft intends to finish all the tasks of this extensive project in 2014.

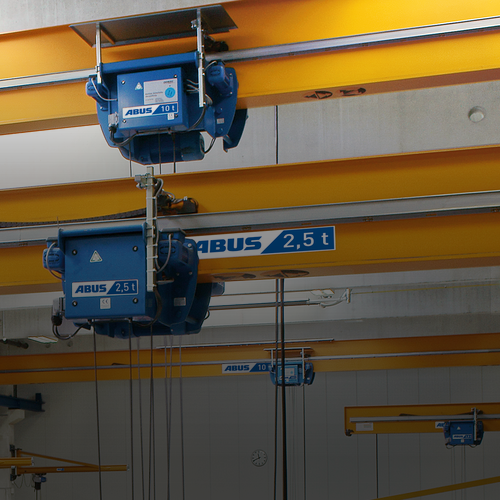

employed in the machinery hall had already an important task to fulfil in the first construction phase of the power plant: materials and machines such as the concrete elements for the base of the turbine were transported on the 75 metres long crane track to the building site. The EOT crane is a double girder crane type ZLK, box girder design, SWL 75 tonnes, with a span of 12.5 metres. The crane features a double rail trolley with twin hoist and an additional wire rope hoist (load capacity 10 tonnes) acting as auxiliary hoist. The crane comes also with a walkway and crane lights. Getting the crane to the site was a particular challenge: The crane was shipped to the nearest harbour and then transported on small country roads as soon as the weather permitted to do so. The crane will have to carry out its most ambitious task in 2014 when the construction works are finished and the turbine is put into place. In order to accomplish this sensitive transport task the crane has been provided with radio remote control and an ABULiner frequency converter for crane and trolley travelling. After that the crane will only be used for maintenance works of the turbine.